Mines switching between gold/coal/iron ore suffer from "dedicated-machine" inefficiency. How can one device handle "coal mining → ore extraction → sludge cleaning"? The narrow vein mining excavator’s universal attachment system breaks this deadlock—quick-swapping tools to cover all ores, slashing downtime and costs.

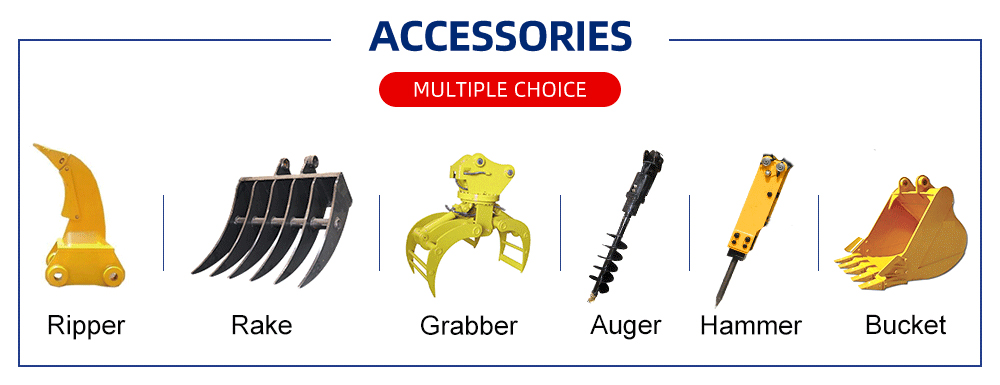

Versatility Core: Attachments for Diverse Challenges

Universal Coal-Rock Bucket: Tungsten-coated surface digs soft coal and fractures medium-hard rock for coal/metal ore stripping.

Hydraulic Breaker: Cracks iron ore with high-frequency impacts.

Grapple: Clears debris/timber in open-pit mines.

Accessory matrix includes: Rake (waste consolidation), Auger (narrow-tunnel drilling), Hydraulic Shear (light crushing/sorting).

Case Study: Zambia Gold Phoenix Saves $120k/Year

Zambia’s Gold Phoenix Mine struggled with inefficient equipment swaps. After adopting narrow vein mining excavator:

l3-minute attachment changes replaced "one-machine-per-ore"

lDay: Breaker for hard ore → Noon: Grapple for debris → Night: Bucket for transport

lSaved $120k/year by eliminating 2 drill jumbos, cutting idle time 60%.

Proving: Universal attachments transform narrow vein mining excavator from multi-functional to profit-multiplying.

Why Choose Narrow Vein Mining Excavator?

Traditional gear delays operations with slow attachment changes and poor adaptability. The narrow vein mining excavator features:

lPatent quick-coupler (3-minute swaps)

lTunnel-optimized tools (2.8m min. turning radius)

lOne-machine coverage for gold/coal/iron ore—maximizing ROI.

As mining modernizes, narrow vein mining excavator’s "universal attachments + high adaptability" make it the global cost-efficiency champion. Consult now for tailored solutions—stay ahead in multi-ore operations!